Company history and outlook ISOLITH

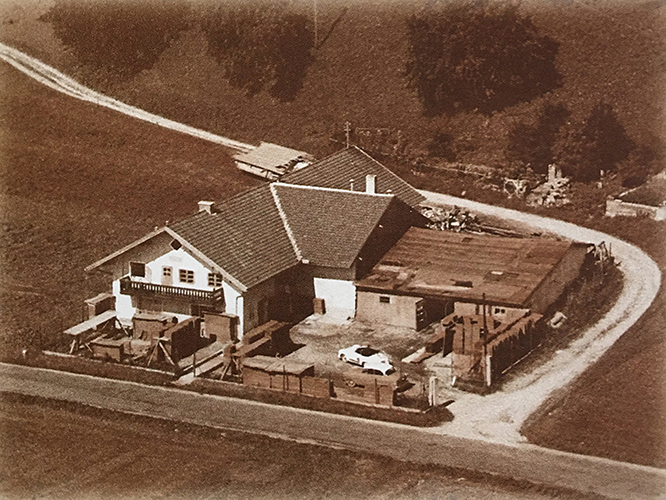

Based on the idea of using the good properties of wood for thermal insulation in house construction, the farmer and ÖBB employee Michael Hattinger developed a process to produce insulation boards with wood, water and cement. Convinced of this product, the company Michael Hattinger, lightweight board production, was founded in March 1956. At that time the company already employed seven people. The production took place in laborious manual labor. The young company lacked the necessary financial means for machines. Nevertheless, the young entrepreneur managed to establish the product on the market, because the wood wool lightweight panel was the most widely used insulation material on the building materials market at the time. Always anxious to respond to the wishes of customers and the market, the production of multilayer boards (wood wool boards with EPS core) brought about an important expansion of the range in the 1960s.

The CEWOOD acoustic panels are a long-lasting and natural material made of high-quality wood wool and cement. With the combination of fire resistance and good sound and thermal insulation properties, the product offers a wide variety of design solutions. Acoustic panels are widely used in the interior design of public and residential buildings, they are environmentally friendly and harmless to health. The panels are very suitable for wall cladding and suspended ceiling constructions. Due to their natural composition and excellent properties, the panels are often used in rooms with increased noise pollution, where sound insulation and sound absorption are important. The panels do not change their properties in rooms with increased humidity, they absorb the excess humidity and ensure a pleasant microclimate, as is typical for rooms with wooden cladding. 15, 25 and 35 mm thick panels made of 1.5 and 1 mm thick wood wool are used for the ceiling finishing. All CEWOOD products meet the requirements of EN 13168.

The CEWOOD acoustic panels are a long-lasting and natural material made of high-quality wood wool and cement. With the combination of fire resistance and good sound and thermal insulation properties, the product offers a wide variety of design solutions. Acoustic panels are widely used in the interior design of public and residential buildings, they are environmentally friendly and harmless to health. The panels are very suitable for wall cladding and suspended ceiling constructions. Due to their natural composition and excellent properties, the panels are often used in rooms with increased noise pollution, where sound insulation and sound absorption are important. The panels do not change their properties in rooms with increased humidity, they absorb the excess humidity and ensure a pleasant microclimate, as is typical for rooms with wooden cladding. 15, 25 and 35 mm thick panels made of 1.5 and 1 mm thick wood wool are used for the ceiling finishing. All CEWOOD products meet the requirements of EN 13168.

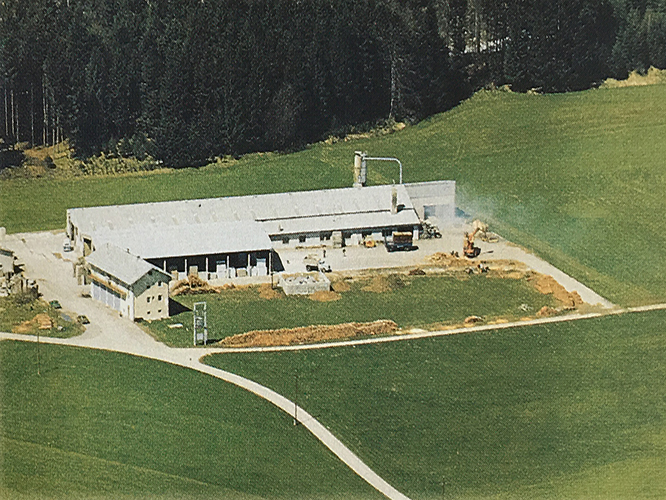

In 2017 and 2018, the mixing plant was renewed and a new color coating plant including a drying tunnel with a fully automatic stacking system was built. In recent years, production at ISOLITH has specialized more and more in multilayer panels for the building construction sector and has pushed the production of single-layer acoustic panels into the background. In order to still be able to offer a wide range, ISOLITH decided to enter into a partnership with CEWOOD. With the products for room acoustics and design from CEWOOD, we now also offer wood wool panels for this area of application. The company, which employs around 30 people, is still exclusively family-owned and is still managed by Manfred Hattinger. The future of ISOLITH lies in the production of products according to the latest and most modern knowledge. Research and development move incessantly and require continuous adaptation and development. The focus is always on handshake quality, great economic understanding and the maintenance of values such as trust, reliability, fairness, tradition, regionality and environmental awareness. The strong partnership with the Austrian building materials trade (ISOLITH is a sponsor of the VBÖ – Association of Building Material Traders Austria) and the close contact with the processing customers ensure constant growth at the cutting edge.